A Blog with topics for those interested in improving your Morgan

Monday, 1 November 2021

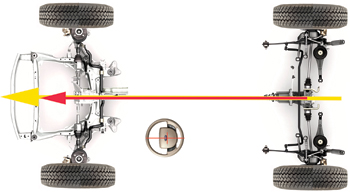

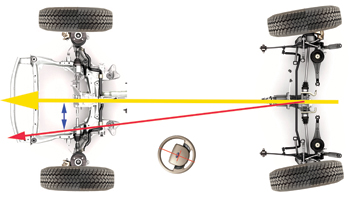

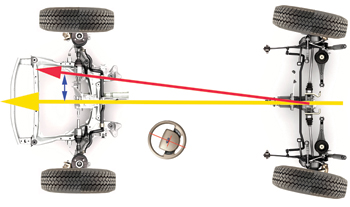

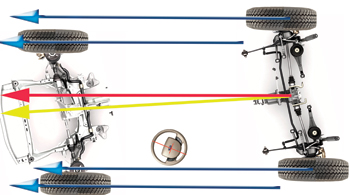

CHASSIS - Alignment Specs: Thrust Angle and Setback

Saturday, 30 October 2021

The Morgan Roadster Limited Slip Differential

The Morgan Roadster Limited Slip Differential.

While I was on the shoot, MMC engineers had Frog Mog up on a ramp and ascertained the noise was coming from the rear axle Limited Slip Differential.

Having explained it was quite normal and not unusual ”they all do that sir”, and not dangerous to drive."

Noisy Limited Slip Differentials During Cornering.

They provide better traction on slippery surfaces. During a turn the wheel on the outside ~ 10% faster than the inside wheel.

By overcoming Clutch Tension the two wheels can rotate a different speeds during turns.

The Roadster 100 Differential contains friction plates when other types may contain Cones.

A multiple disc clutch differential consists of two sets of multiple disc clutch packs located on each of the two side gears.

These clutch packs have friction plates splined to the side gear, interlaced with steel plates that have tabs locking them to the differential case.

The Spider and Side Gears are bevelled. The turning pinion gears force the side gears outwards towards the case.

The mechanical force of the bevelled gears and spring tension apply the clutch. For a set of friction plates to slip they must overcome the preset spring tension.

Service the differential fluid at recommended intervals. Special Limited-Differential Fluid compliments the engagement and release of the limited slip components.

Adding standard differential fluid to a limited slip differential can result in noise and vibration while turning.

A vehicle with a Limited Slip Differential 'Chatters' while only taking turns. Using the wrong differential fluid causes chatter.

.........................................................

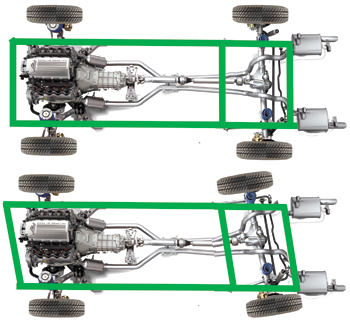

A Morgan Plus 4 Exploded Diagram Showing both Normal & Limited Slip Differential Options.

A Morgan Dana Spicer Rear Axle Diagram with a Cone Type Limited Slip Differential.

These axles were supplied by the Spicer Axle Australia PTY Ltd. The 0061 LSD model is used on all Roadster 100's has a gearing Ratio of 3.73 : 1

Interesting that the Series 1 Roadster used a 0060 model with a Ratio of 3.08 : 1.

1. The Morgan Motor Company "standard" in the 'Dana' Axle from Spicer Axle Australia PTY Ltd. which is the Friction Clutch Type, and is quite susceptible to begin set up wrong from the start. Some versions need a special additive in the oil.

2. The Quaife torque biasing diff recommended by Tim (which I fully endorse, by the way) is a much better option for most applications and Morgans in particular.

4. When you reach the point at which you do break traction , now both rear wheels will be spinning, and you had better be used to this , and good at catching it. If you are, and can, then there is no doubt that an LSD is a great addition to your car and will enhance your Morgan driving experience.

I summary, think about what you want from your Morgan and how you drive it. If you regularly go off road then an LSD provides much needed traction, if you compete with the car then it gives far superior traction out of corners, but if you just want to tour around (at legal speeds?) and are a fair weather driver, you might not get as much from it.

I think the cause of the juddering on a LSD is that one of the wheels doesn't 'freewheel' and ends up been dragged along at the speed of the (slower moving) inner wheel.

Dannyboyo at PistonHeads

Ivan at PistonHeads

Thursday, 28 October 2021

Visiting The Morgan Factory with Combat Stress & MOG Magazine.

Combat Stress Building a Morgan

Good afternoon all,

I just thought I’d give you a quick update on how the photo shoot for our fund raising calendar went at Morgan Motor Company on Wednesday.

A Very Early Arrival

The run up was pretty uneventful until it came time to park. Upon arrival I swung into the car park ready to reverse into my chosen spot.

Hard lock complete I started to move back and heard a clonking sound from behind me, checking my mirrors again, saw nothing, started maneuvering again only to hear the awful noise, popped into neutral, applied hand brake got out and checked around/under the car, still nothing!! How bizarre.

Undeterred but confused I returned to the drivers seat to finish parking only to hear the noise again, straightened up and silence returned, so I parked up and went to meet the team inside.(more on the noise later).

The Factory Visitor Center Car Sales Area.

The Visitors Car Park

The New Visitor Center Refectory

The Photographers Team Gathering.

'Masking Up' before heading to the Factory Workshops

Everyone arrived on time, We split the team in 2 and moved off with our respective photographers(3 per team), Veterans(3 per team), MOG magazine and MMC representatives,

My Team taking the Visitor's Route to the Factory.

Heading for their Work Stations to begin building.

Mmmm! What is going on over there?

Our task was to complete 6 separate shots per team depicting our intrepid volunteers from Combat Stress Building a Morgan for the calendar.

I headed up team A.

We were tasked with the Chassis, Engine, Panel Shaping, Louvre Manufacture, Ash Wheel Arch Manufacturing and finally Quality Control/Detailing and Inspection.

We were in the Chassis Shop with its line of CX Chassis in build, but it was soon time to cut some Louvres into a Bonnet

As we worked our way around the factory I was really taken back by how quickly the student photographers picked up the baton from their briefing and our CS Volunteers became fully fledged Morgan Motor Engineers, it was a joy to watch and be a part of.

Checking the Bar Codes.

Nigel, undertaking some Quality Control

Readying themselves to tackle that Engine.

Up on the Gantry, ready for the car.

We are actually undertaking the Quality Control and Final Detailing

Suffice to say Team A&B completed the shots required and every one enjoyed a quick look around the museum and shop before a hearty and well earned lunch.

The Teams making their way to Lunch

Some interesting items viewed along the way.

A Display of Polished Dashboards

During the return to the Visitor Center much interest was shown in the very limited edition of only 8 New Plus Four CX-T (for Trials)

I’ll leave the story there as it will be covered with decent photos and editorial in the December edition of MOG Magazine.

If you haven’t subscribed to receive MOG yet please do so. They support the R100 team in all we do above and beyond the call of duty promoting everything we do.

So please support our worthy cause and order your calendars, photos contained here are clearly mine, taken at random times as we went round, they are not intended for use in the calendar, don’t let their quality put you off, every one was taken with pride and a smile.

All the best

Terry

Now back to Frog Mogs rear end noise!

While I was on the shoot MMC engineers had Frog Mog up on a ramp and ascertained the noise was coming from the rear axle Limited Slip Differential.

Having explained it was quite normal and not unusual ”they all do that sir”, and not dangerous to drive, I undertook to get it looked at in a couple of weeks time at Williams when she’s in for her annual service and MOT.

I didn’t hear another peep from behind until I put it into reverse on full lock to get into the garage at home and there it was again!

Oh well I’m sure it will still be there tomorrow!!

The Morgan Centenary Trim Pack

The Morgan Centenary Trim Pack During The Centenary of The Morgan Motor Company the owners of new Morgans in build were offered the variou...