Combat Stress Building a Morgan

Good afternoon all,

I just thought I’d give you a quick update on how the photo shoot for our fund raising calendar went at Morgan Motor Company on Wednesday.

The Mission Statement and Advertisement.

Well it was an early start as I headed out from Lymington.

Our planned meet time with the team at the Morgan visitors center was 09.00.

A Very Early Arrival

The run up was pretty uneventful until it came time to park. Upon arrival I swung into the car park ready to reverse into my chosen spot.

Hard lock complete I started to move back and heard a clonking sound from behind me, checking my mirrors again, saw nothing, started maneuvering again only to hear the awful noise, popped into neutral, applied hand brake got out and checked around/under the car, still nothing!! How bizarre.

Undeterred but confused I returned to the drivers seat to finish parking only to hear the noise again, straightened up and silence returned, so I parked up and went to meet the team inside.(more on the noise later).

The Factory Visitor Center Car Sales Area.

The Visitors Car Park

The New Visitor Center Refectory

The Photographers Team Gathering.

The First Veteran knows how to wear his Combat Stress Cap.

Anticipation of a Busy Day Building Morgans.

'Masking Up' before heading to the Factory Workshops

Everyone arrived on time, We split the team in 2 and moved off with our respective photographers(3 per team), Veterans(3 per team), MOG magazine and MMC representatives,

My Team taking the Visitor's Route to the Factory.

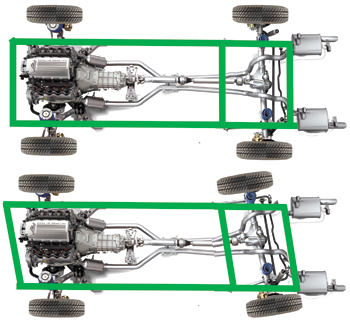

Passing a Chassis & Finished Car Storage Area.

Receiving some Technical Information along the way.

Familiarising themselves with their surroundings.

Heading for their Work Stations to begin building.

Mmmm! What is going on over there?

Our task was to complete 6 separate shots per team depicting our intrepid volunteers from Combat Stress Building a Morgan for the calendar.

I headed up team A.

We were tasked with the Chassis, Engine, Panel Shaping, Louvre Manufacture, Ash Wheel Arch Manufacturing and finally Quality Control/Detailing and Inspection.

We were in the Chassis Shop with its line of CX Chassis in build, but it was soon time to cut some Louvres into a Bonnet

As we worked our way around the factory I was really taken back by how quickly the student photographers picked up the baton from their briefing and our CS Volunteers became fully fledged Morgan Motor Engineers, it was a joy to watch and be a part of.

Checking the Bar Codes.

Multi Tasking to get it right.

Tightening the Compression Bolts on the Rear Wheel Arch Laminating Jigs

Nigel from MOG was in my team, recording step by step what was happening with a view to make a story from the proceedings as they unfolded before us.

Nigel, undertaking some Quality Control

Job Done - Tough Work but Very Satisfying.

And no Glue spilled on the floor below.

Although our Combat Stress volunteers had challenges in their lives honestly you wouldn’t have known as they were determined to enjoy the spirit of the day getting into every shot no matter how tricky access seemed, they really were characters, filling the day with one liners and anecdotal stuff that made everyone on the team smile and feel at ease.

Readying themselves to tackle that Engine.

Up on the Gantry, ready for the car.

Now that we've Built it, Its time to try it for size.

We are actually undertaking the Quality Control and Final Detailing

Suffice to say Team A&B completed the shots required and every one enjoyed a quick look around the museum and shop before a hearty and well earned lunch.

Inspecting the Range of Models in Dispatch.

The Teams making their way to Lunch

Some interesting items viewed along the way.

A Little Offcut of Veneer

A Display of Polished Dashboards

A Place for Everything

During the return to the Visitor Center much interest was shown in the very limited edition of only 8 New Plus Four CX-T (for Trials)

Our final shots required every student and CS volunteer to be photographed in a finished Morgan. Alas it was Blue but there were smiles abound as they each had the opportunity to sit in an British built Iconic beauty.

Then Nigel offered a quick spin around the block to the team in his Plus 8, one by one they came back looking windswept and disheveled but none the worse for the quick blast around the block.

I’ll leave the story there as it will be covered with decent photos and editorial in the December edition of MOG Magazine.

If you haven’t subscribed to receive MOG yet please do so. They support the R100 team in all we do above and beyond the call of duty promoting everything we do.

So please support our worthy cause and order your calendars, photos contained here are clearly mine, taken at random times as we went round, they are not intended for use in the calendar, don’t let their quality put you off, every one was taken with pride and a smile.

All the best

Terry

Now back to Frog Mogs rear end noise!

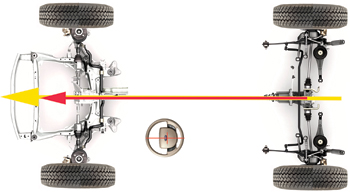

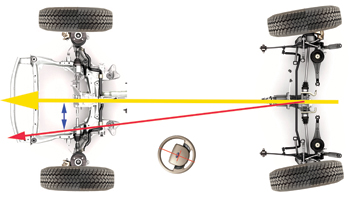

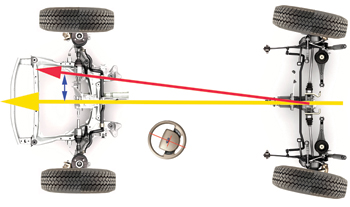

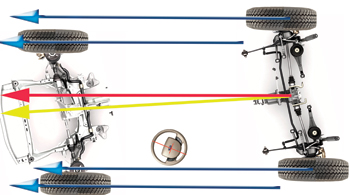

While I was on the shoot MMC engineers had Frog Mog up on a ramp and ascertained the noise was coming from the rear axle Limited Slip Differential.

Having explained it was quite normal and not unusual ”they all do that sir”, and not dangerous to drive, I undertook to get it looked at in a couple of weeks time at Williams when she’s in for her annual service and MOT.

I didn’t hear another peep from behind until I put it into reverse on full lock to get into the garage at home and there it was again!

Oh well I’m sure it will still be there tomorrow!!